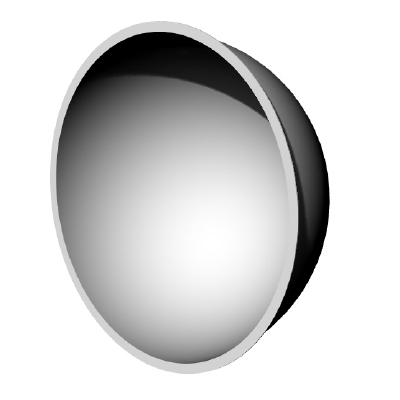

This page showcases a standard 3.2M dome but all designs can be fully customized depending on requirements. The domes can be sold separately or as part of of a visual set up including projectors. Our domes are designed to be easy to ship and install but have been engineered to create a flawless projection surface.

Standard Dome sizes available: 2.2M, 3,2M, 4.0M, 5.0M, 7.0M, 9.0M, 10.0M, 11.0M, 12.0M, 13.0M, 14.0M.

Full Hemisphere, Truncated Hemisphere and Panadome. Hard Shell and Inflatable configurations available.

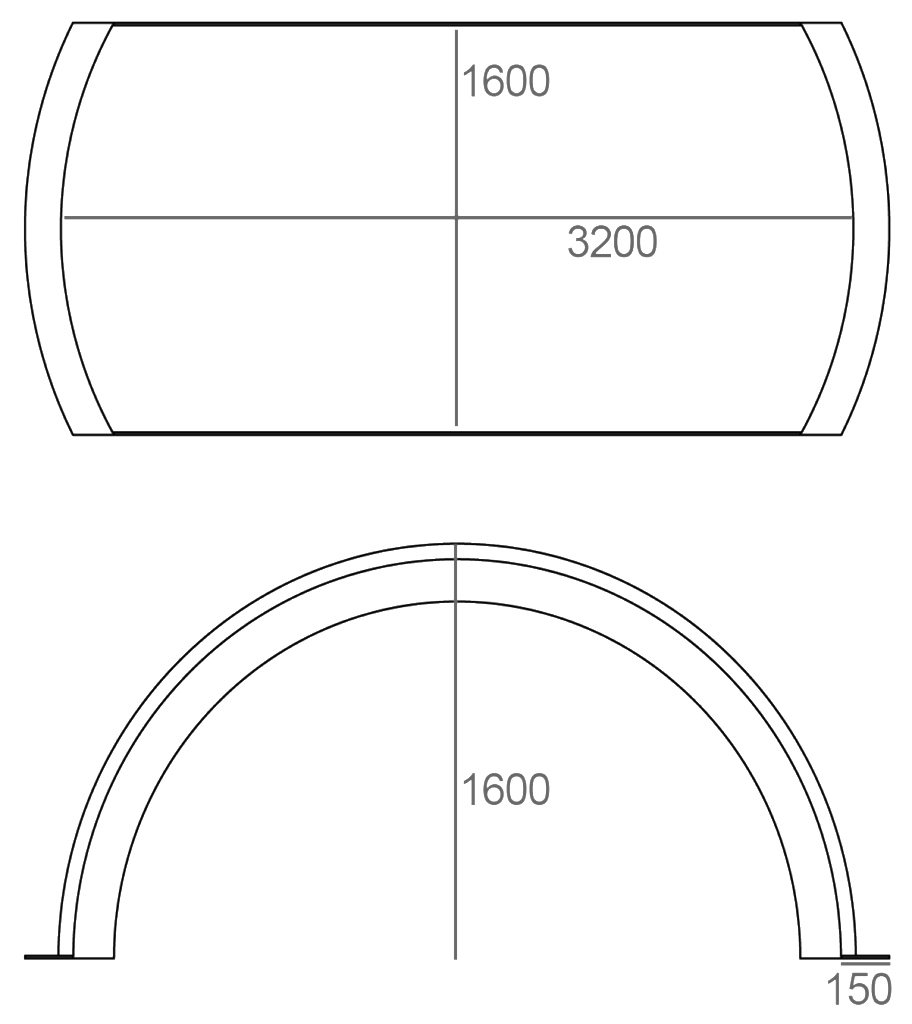

3.2m HS Full Dome

Our full immersive projection dome is manufactured from a range of materials with precise specifications determined by dome size, shape and use.

The standard construction:

Two layers of polyester gel coat, covered with multiple layers of woven glass fibre sandwiched between chopped strand matt using a polyester resin matrix. Extra laminate is applied at bolting positions and in high load areas for added strength.

The laminate is placed down and consolidated by hand to ensure consistency of wall thickness and to eliminate air pockets. The surface is then finished with a polyester flow coat.

Custom finishes include:

Carbon fibre/ foam sandwich construction using an epoxy resin matrix that is vacuum bagged down to give 14 psi of consolidating pressure. This typically gives a 70% weight saving over the standard construction and increases the overall stiffness. The inside and outside surfaces are then finished with a polyurethane paint system.

Screen surfaces are textured and coloured to allow maximum display capability for given projection brightness, contrast and content.

Total assembled weight: 140kgs

Total number of component parts: 4

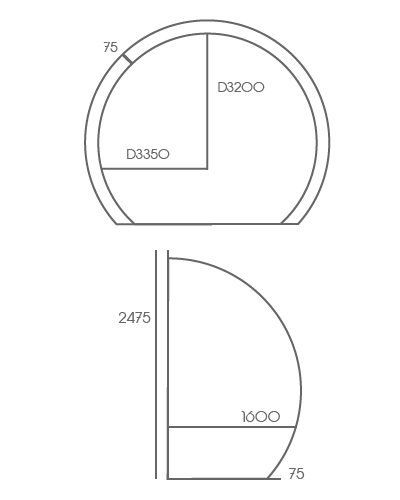

3.2m HST Truncated Dome

Our immersive projection dome is manufactured from a range of materials with precise specifications determined by dome size, shape and use.

The standard construction:

Two layers of polyester gel coat, covered with multiple layers of woven glass fibre sandwiched between chopped strand matt using a polyester resin matrix. Extra laminate is applied at bolting positions and in high load areas for added strength.

The laminate is placed down and consolidated by hand to ensure consistency of wall thickness and to eliminate air pockets. The surface is then finished with a polyester flow coat.

Custom finishes include:

Carbon fibre/ foam sandwich construction using an epoxy resin matrix that is vacuum bagged down to give 14 psi of consolidating pressure. This typically gives a 70% weight saving over the standard construction and increases the overall stiffness. The inside and outside

surfaces are then finished with a polyurethane paint system.

Screen surfaces are textured and coloured to allow maximum display capability for given projection brightness, contrast and content.

Total assembled weight: 120kgs

Total number of component parts: 4

Truncated Diagram

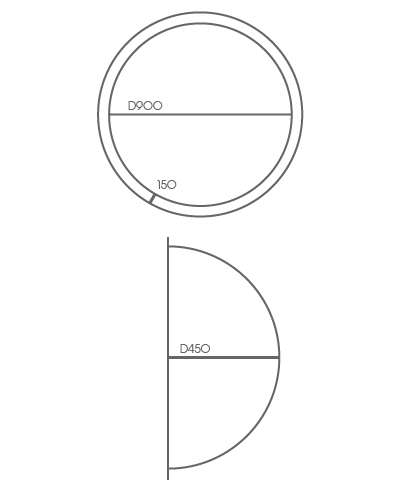

3.2m HS Panadome

Our immersive projection dome is manufactured from a range of materials with precise specifications determined by dome size, shape and intended use.

Basic construction method:

Two layers of polyester gel coat, covered with multiple layers of bi-axial woven glass fibre sandwiched between chopped strand matt using a polyester resin matrix. Extra laminate is applied at bolting positions and high load areas for added strength.

The screen surface is textured and coloured to allow maximum display capability for given projection brightness, contrast and content.

Weight saving method:

A lightweight version is available for use on motion platforms or in applications where the strength to weight ratio is critical. The carbon fibre/ foam sandwich construction uses an epoxy resin matrix that is vacuum bagged down to give 14 psi of consolidating pressure.

This typically gives a 70% weight saving over the standard construction and increases rigidity overall.

Domes are shipped in segments with pre-formed lugs, flanges and all necessary fixings. While customer installation is possible, we recommend the use of our specialist installation team who will assemble the panadome on site, fill joints between segments, ensure a perfect screen surface and apply a non-reflective matt paint finish.

Total assembled weight: 80kgs

Total number of component parts: 2